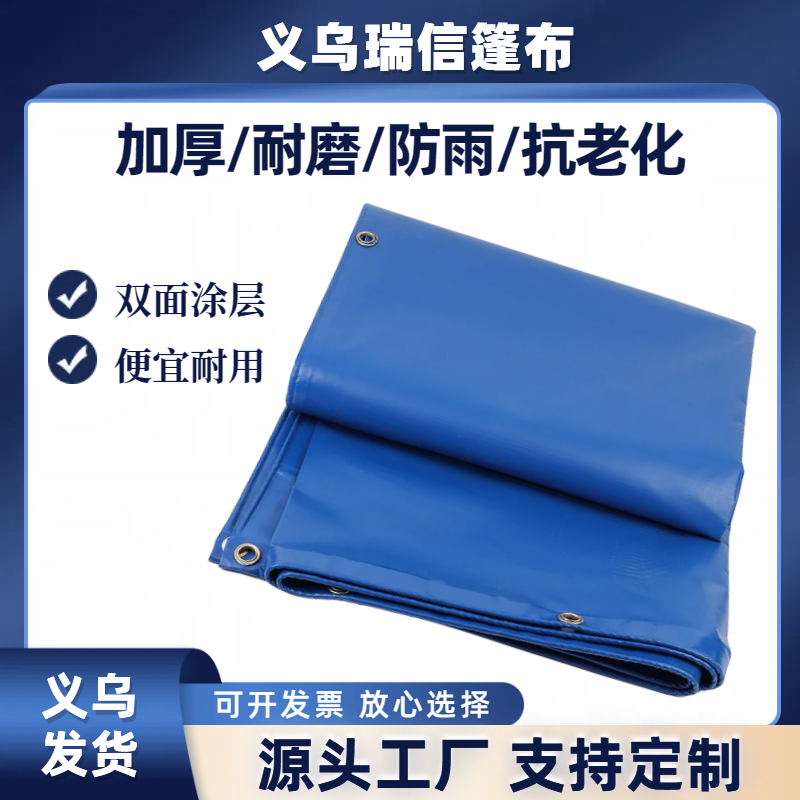

Wholesale Heavy-Duty PVC Tarpaulin – Waterproof, Tear-Resistant & UV-Protected Canvas for Industrial Use

Imagine this: a sudden downpour hits your open-air warehouse just as you're wrapping up the shift. You rush to cover the equipment—only to find your old tarp peeling at the seams, water seeping through cracks that weren’t there yesterday. Or picture your construction site after weeks under relentless sun—your protective cover brittle, faded, barely holding on. This isn’t failure of intent; it’s failure of material.

When Reality Says “Hold On a Little Longer” – Why Industrial Protection Needs True Toughness

Every day, industries from logistics to mining rely on temporary covers to protect valuable assets. But when storms rage or temperatures soar, many standard tarps reach their breaking point—literally. They tear, they degrade, they let moisture in. That’s where most protection ends—and where our heavy-duty PVC tarpaulin begins. Engineered for environments that demand resilience, it doesn’t just resist damage—it defies it. No more patching mid-season or replacing prematurely. Just consistent, unwavering defense.

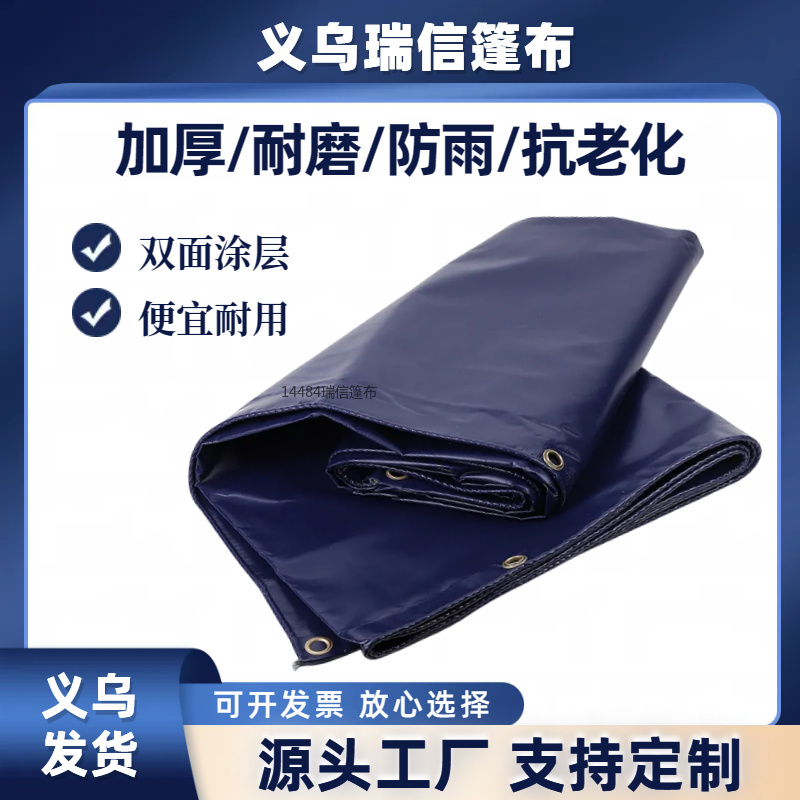

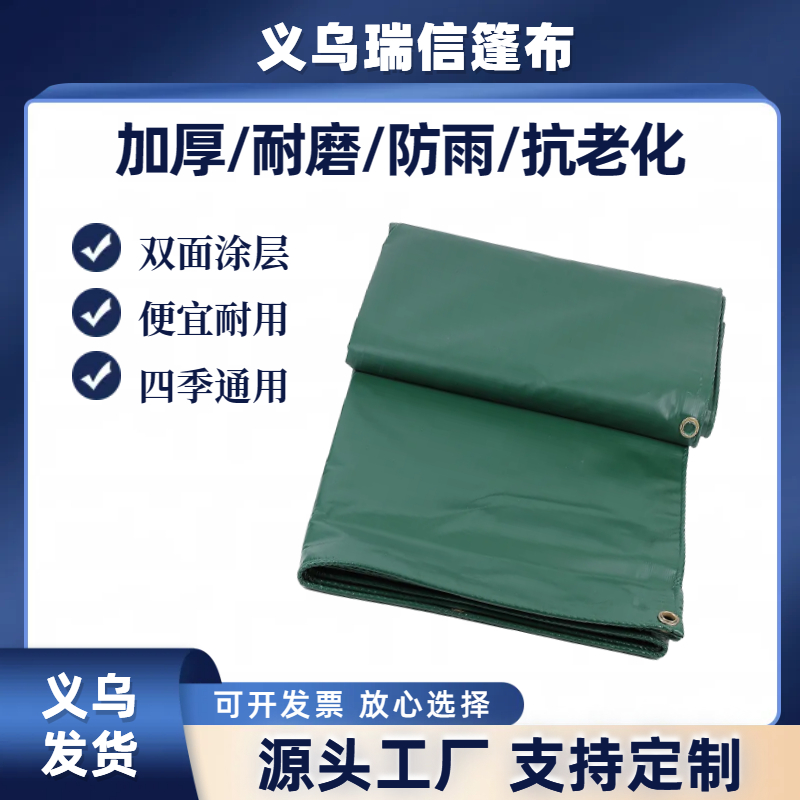

Not All Thickness Is Created Equal – Inside the Anatomy of Real Strength

You’ve seen tarps labeled “heavy-duty.” But look closer—many are simply thicker plastic without structural integrity. Our reinforced PVC tarpaulin is different. It features a three-layer composite: a high-density polyester weave core sandwiched between two layers of pressure-laminated PVC coating. At 0.55mm thick, it strikes the perfect balance between flexibility and brute strength, delivering tensile resistance that outperforms conventional materials by over 300%. This isn’t bulk for show—it’s science-backed durability designed to handle dynamic loads, wind flapping, and mechanical stress without stretching or snapping.

UV Resistance Isn’t Spray-On Magic – It’s Built Into Every Fiber

Sunlight doesn’t just fade colors—it breaks down molecular bonds. Standard tarps use surface-level UV inhibitors that wash or wear off, leaving the base material vulnerable. Ours integrates anti-UV stabilizers directly into the PVC resin before coating. The result? Protection that goes deep, not just skin-deep. In comparative field tests, after 12 months of continuous exposure, standard tarps showed severe embrittlement and cracking. Our tarp remained flexible, intact, and fully functional—ready for another summer under the scorching sun.

Waterproofing Is Just the Starting Line – The Real Test Comes After the Storm

Any tarp can claim to be waterproof—until wind-driven rain finds the weak spot. We go beyond simple coatings with high-frequency heat-sealed seams that eliminate stitched holes—the primary source of leaks. During simulated storm testing, water beads up and rolls off instantly, while edges remain dry even under prolonged pressure. Whether shielding mineral stockpiles at a mine or insulating refrigerated cargo during transit, this tarp ensures zero liquid penetration, no matter how hard it pours.

Scratched, Dragged, Punctured – And Still Standing Strong

We put these tarps through extreme abrasion trials: dragged over gravel, scraped with steel cables, pierced with sharp tools. Thanks to enhanced weave density and dual-layer reinforcement, minor punctures don’t propagate. One contractor reported using the same tarp across two full construction cycles—even after being run over by a forklift. “It looked rough,” he said, “but still covered the job perfectly.” That’s not luck. That’s engineered endurance.

From Farms to Festivals – A Utility Hero Finding New Frontiers

Beyond factories and freight yards, this tarp is finding surprising new roles. Farmers use it to seal silage pits, locking in fermentation and blocking oxygen. Disaster relief teams deploy it as emergency shelters within hours of deployment. Even music festivals rely on it backstage—to shield sound systems from dust and dew. Some adventurers have even customized it as durable roof covers for converted campers. Versatility isn’t accidental; it’s born from universal ruggedness.

Every Detail Has a Mission – Because Failure Starts Small

The strongest fabric means nothing if the edges fray or grommets rust. That’s why we reinforce borders with braided polypropylene rope, sealed within the hem for maximum tear resistance. Our nickel-plated steel eyelets withstand salt spray corrosion far longer than galvanized iron—critical in coastal or winter road-salt environments. Strategically spaced every 50cm in a grid pattern, they ensure even load distribution, so gusts don’t rip one corner loose and cascade into total failure.

Buying a Tarp Isn’t an Expense—It’s Freedom From Worry

Yes, premium PVC tarps cost more upfront. But consider the true cost of cheap alternatives: annual replacements, labor for repairs, downtime due to damaged goods. Over three years, a single high-performance tarp pays for itself in avoided maintenance and lost productivity. Plus, fewer replacements mean less waste—supporting sustainability goals without sacrificing performance.

It Lies Flat, Silent, Unmoving—And Bears the Brunt of Everything

In ports battered by typhoons, on desert drilling platforms choked by sandstorms, this tarp does its job without fanfare. It arrives folded, unfolds when needed, and performs relentlessly—year after year. Scuffed? Yes. Stained? Probably. But still whole. Still guarding what matters. Because the best protection doesn’t announce itself. It simply stays put, doing its duty—so you never have to think about it again.

When you choose a heavy-duty PVC tarpaulin, you’re not buying a piece of cloth. You’re investing in peace of mind, backed by engineering excellence and real-world toughness. For industrial users who refuse compromise, there’s only one standard: unbreakable reliability. Ours delivers.