Understanding the Risks

Industrial equipment operates under strenuous conditions, often exposed to environmental elements that can lead to significant damage. Among these risks, exposure to moisture and humidity is particularly detrimental. When equipment is not adequately protected, moisture can seep into critical components, leading to various issues.

Corrosion and rust formation are common problems resulting from prolonged exposure to wet conditions. Metal parts oxidize over time, compromising their structural integrity and functionality. Additionally, electrical short circuits become prevalent when water infiltrates the electrical systems, posing both safety hazards and potential operational failures.

Financial Implications of Equipment Failure

The consequences of failing industrial equipment extend beyond immediate repairs. Direct costs such as repairs and replacements quickly accumulate, impacting your budget. However, equally concerning are the indirect costs: downtime and lost productivity can disrupt operations, causing delays and financial losses.

Considering these risks, implementing effective waterproofing strategies for your industrial tools and machinery becomes crucial. The right protective measures can prevent costly damages and maintain seamless operations, ultimately safeguarding your investments.

Waterproofing Technologies and Methods

A variety of solutions exist to protect industrial equipment from moisture-induced damage. Each method offers unique advantages, ensuring there is an appropriate solution for different needs.

Overview of Waterproofing Solutions

Coatings and sealants are a popular choice, creating a barrier that prevents moisture from contacting sensitive parts. Enclosure and housing solutions offer physical protection by isolating equipment in waterproof containers. Protective covers and tarpaulins serve as an additional layer, shielding machines from direct exposure to environmental elements.

Comparative Analysis

Each method has its pros and cons. Coatings and sealants provide comprehensive coverage but may require regular reapplication. Enclosures ensure maximum protection but can be bulky and limit accessibility. Protective covers like PVC tarpaulins are versatile, easy to use, and suitable for various equipment types.

Benefits of Using PVC Tarpaulin

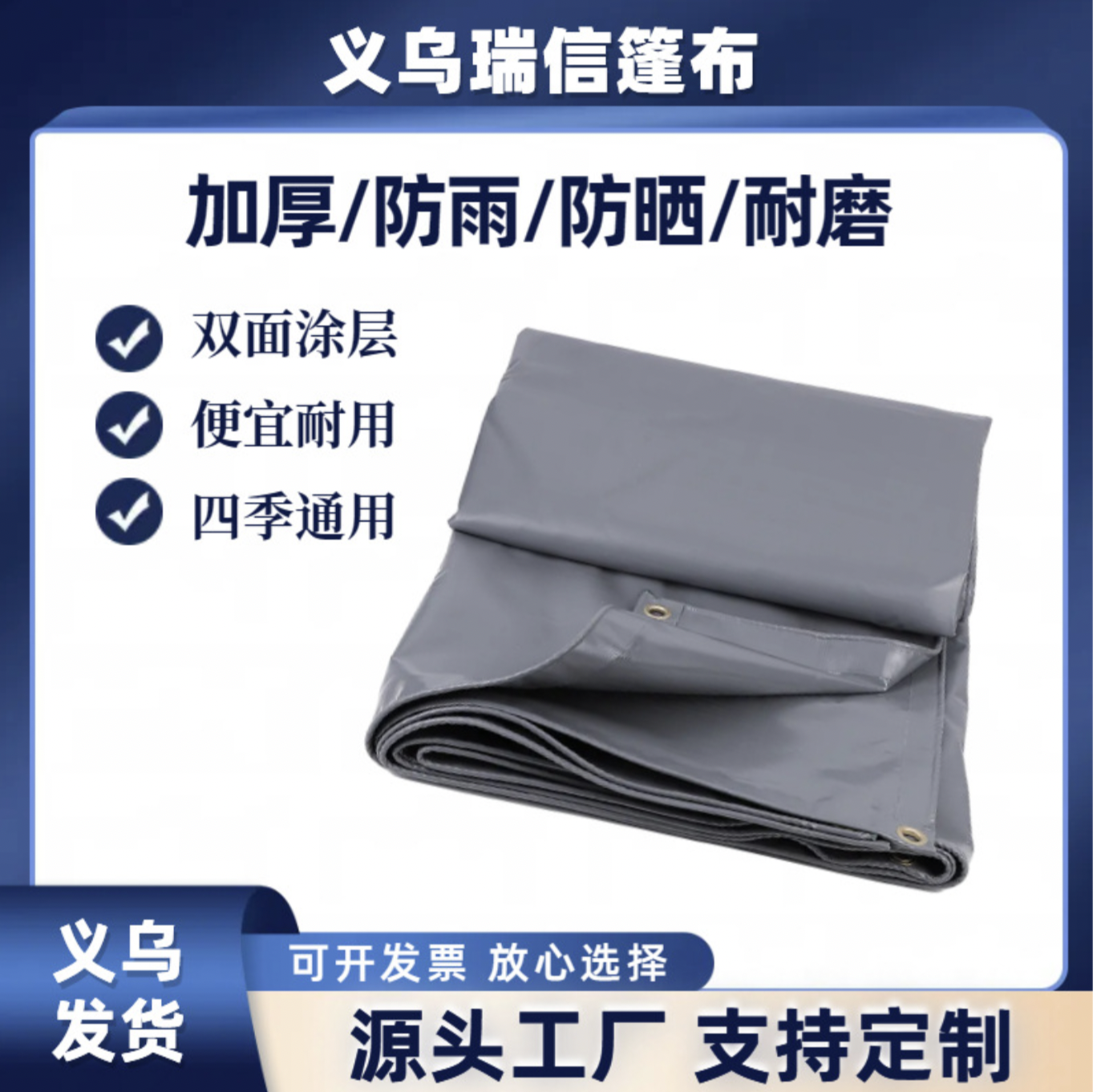

PVC tarpaulins stand out due to their durability and strength, which make them ideal for harsh environments. This material resists wear and tear, extending the lifespan of your protective measures even when faced with challenging conditions.

Waterproofing Capabilities

PVC tarpaulins form an effective barrier against water and moisture. Their impermeable nature ensures that equipment remains dry, minimizing corrosion and other moisture-related damages. Moreover, they offer UV resistance, protecting machinery from sun damage—a key factor in outdoor applications.

How Our PVC Tarpaulin Safeguards Your Assets

Our thickened waterproof PVC grey tarpaulin offers customizable solutions designed to fit various equipment sizes perfectly. These tailored covers are easy to install and remove, providing convenience while ensuring robust protection. Whether you need to shield small devices or large machinery, our tarpaulins meet diverse requirements.

Case Studies and Testimonials

Real-world examples highlight the effectiveness of our products. Clients have shared positive feedback, noting the enhanced durability and reduced maintenance costs after adopting our tarpaulin solutions. Customer satisfaction rates remain high, reaffirming the value our products bring to industrial operations.

Implementation Best Practices

Proper implementation of PVC tarpaulin involves several steps. Begin by measuring and cutting the tarpaulin to match your equipment’s dimensions accurately. Securing the tarpaulin properly helps prevent movement, ensuring consistent coverage and protection.

Maintenance Tips

Regular inspection for wear and tear is essential to maintain waterproof efficacy. Cleaning the tarpaulin and storing it correctly when not in use prolongs its life and performance, avoiding unexpected vulnerabilities during usage.

Future Trends in Equipment Protection

The field of water-proofing materials continues to evolve, driven by advances in fabric technology and smart solutions. Innovations incorporate sensors and automation, offering proactive protection approaches. Adhering to evolving industry standards and regulatory updates ensures compliance and optimal protection practices.

As the industry progresses, embracing new technologies and best practices will enhance your equipment’s longevity and reliability.

Explore Our Product RangeVisit our website to view our full range of products. Take advantage of special offers and discounts available now.

For custom solutions, contact us directly. Our customer support team is ready to assist you with consultation and assessment services tailored to your specific needs.