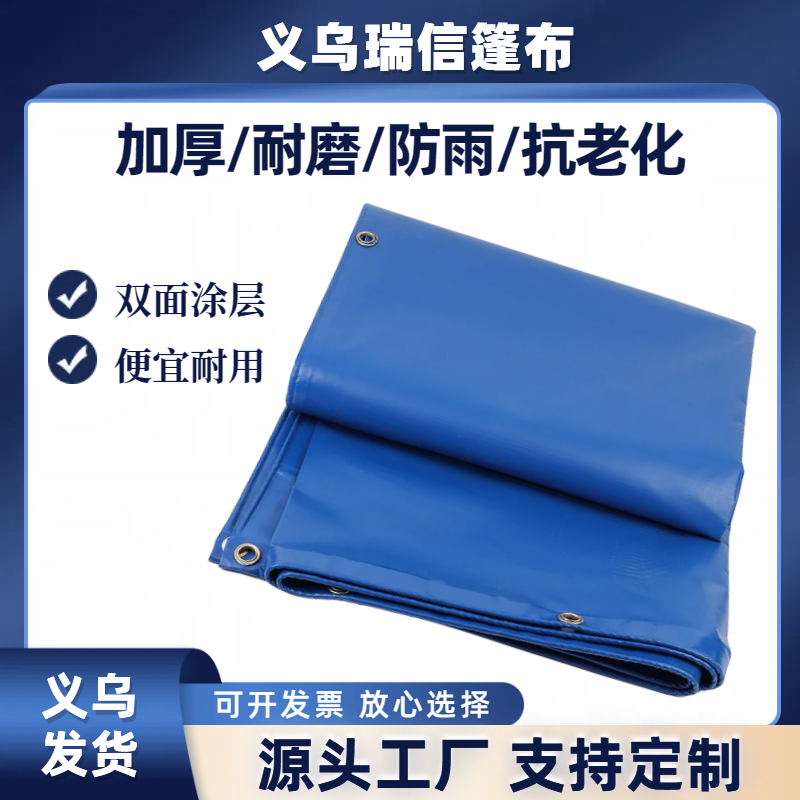

Heavy-Duty Thickened PVC Tarpaulin – Wholesale Waterproof, Sunscreen & Tear-Resistant Canvas

When storms roll in and sunlight beats down relentlessly, what stands between your valuable outdoor assets and irreversible damage? Imagine a construction site where lightweight covers flap wildly in the wind, tearing at the seams. Picture stacked building materials soaked through after a single night of rain. Think of crops battered by hail or warehouse goods ruined by humidity. These aren’t rare scenarios—they’re daily risks for industries and individuals alike.

Enter the unsung hero: the heavy-duty thickened PVC tarpaulin. More than just a cover, it acts as an invisible shield—protecting everything from machinery to harvests with unwavering resilience. This isn’t about temporary fixes; it’s about long-term defense engineered into every fiber.

More Than Just a Plastic Sheet: The Science Behind Triple-Layer Protection

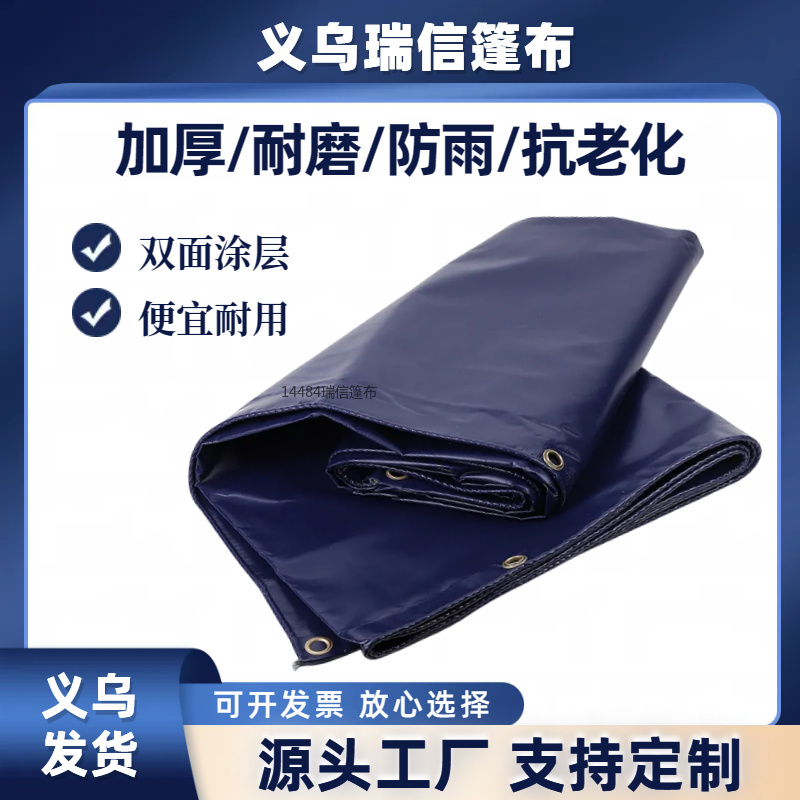

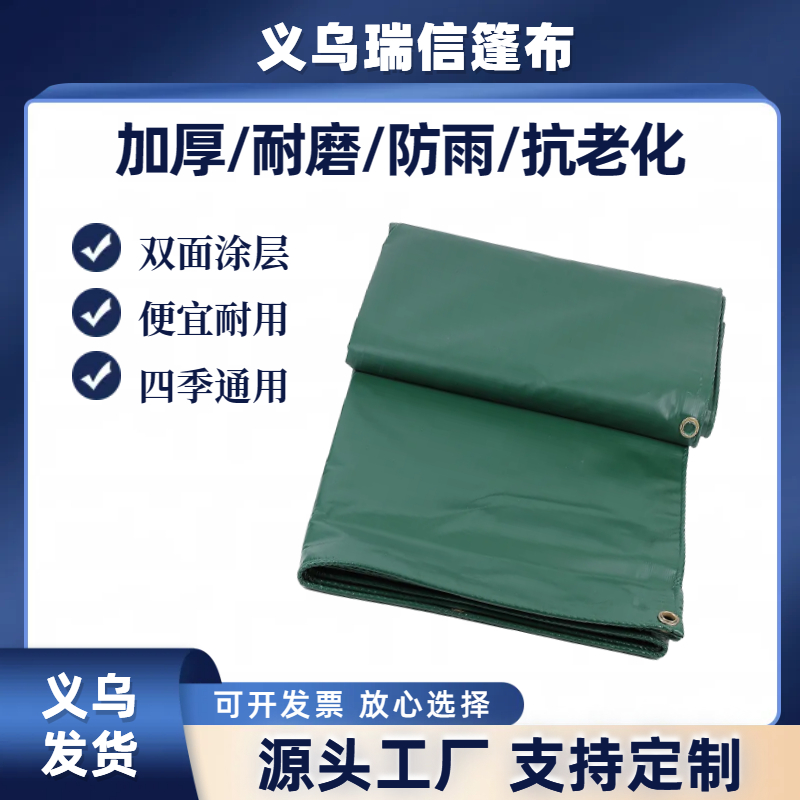

What sets this tarp apart from standard plastic sheets is its intelligent three-layer design. At the core lies a high-density woven fabric, providing structural strength that resists stretching and tearing under pressure. On both sides, a robust PVC coating forms a seamless barrier against water—locking out moisture on a molecular level. Unlike porous fabrics that absorb over time, this surface repels rain like a duck's back.

Beyond waterproofing, the top layer features an advanced UV-inhibiting formula that reflects harmful solar radiation. In accelerated aging tests, standard polyethylene tarps begin degrading within months under constant sun exposure. Our thickened PVC variant, however, retains over 90% of its tensile strength even after 1,500 hours of simulated sunlight. That means no brittleness, no cracking, and no unexpected failures during peak summer heat.

Whether shielding scaffolding at a skyscraper site, covering hay bales in open fields, or creating instant shade for a weekend festival booth, this material adapts effortlessly across environments. Its versatility stems not from luck—but from deliberate engineering.

From Warehouses to Backyard Gardens: Real Stories of Reliability

A logistics manager in Guangzhou once shared how a sudden typhoon tested his entire inventory protection system. While neighboring warehouses reported soaked electronics and dented packaging, his team watched calmly as the storm passed—knowing their goods were wrapped tightly in industrial-grade PVC tarpaulins. Not a single drop got through. Three years later, those same tarps are still in rotation, showing minimal signs of wear.

Meanwhile, a home gardener in Oregon transformed her weather-beaten patio into a semi-enclosed sunroom using custom-cut panels of the same material. Resistant to mold, frost, and relentless Pacific Northwest rains, the tarp has doubled the usable life of her outdoor structure—all at a fraction of the cost of glass or polycarbonate roofing.

And when an event planner in Texas faced a surprise thunderstorm minutes before a farmers’ market launch, she deployed these tarps as emergency canopies. Within ten minutes, booths were dry and operations resumed. One material. Countless uses. Infinite peace of mind.

The Hidden Strength: Why Durability Lives in the Details

True toughness isn’t just about thickness—it’s about how the material holds up where it matters most. Corners and tie-down points endure constant friction and stress. That’s why our tarps feature double-stitched hemming with reinforced thread, preventing unraveling even after repeated use. Stainless steel eyelets resist rust, maintaining integrity season after season.

Equally important is elasticity. Many cheap tarps crack when folded repeatedly due to poor resin formulation. Ours retain flexibility thanks to a balanced polymer blend, allowing them to be rolled, stored, and reused without developing microfractures. When selecting protective covers, buyers should look beyond advertised thickness alone—check the grammage (gsm) and weave density. A truly reliable tarp balances weight, strength, and flexibility.

Smart Procurement: How One Investment Replaces Years of Replacement Costs

Consider this: a budget tarp might save $20 upfront but needs replacing every few months. Over three years, that adds up to six purchases, labor costs, downtime, and ongoing risk. Meanwhile, a premium thickened PVC tarp—though initially more expensive—can easily last 36 months or longer in demanding outdoor conditions. The math speaks for itself: long-term savings exceed 60%, not to mention reduced waste and operational disruption.

Buying wholesale amplifies these benefits. Custom widths minimize overlapping seams—common leak points. Full-roll delivery reduces handling damage and shipping frequency. For large-scale users—from port operators to agricultural cooperatives—bulk procurement isn't just economical; it's strategic.

Looking Ahead: Where Strength Meets Sustainability

The future of protective materials isn’t just about lasting longer—it’s about doing better. Advances in recyclable PVC formulations mean these tarps can now enter circular supply chains instead of landfills. Some manufacturers are already integrating bio-based plasticizers, reducing reliance on fossil fuels.

Tomorrow’s smart tarps may include reflective strips for nighttime visibility on road sites, or antimicrobial coatings suitable for food-grade storage. Imagine a tarp that not only protects cargo but also signals when tension is too high via embedded sensors. The foundation is here: durable, adaptable, and resilient.

Perhaps it’s time we stop thinking of tarps as disposable consumables. With the right engineering, a simple sheet of fabric can become a lasting asset—one that guards investments, withstands nature’s worst, and evolves with innovation. The heavy-duty thickened PVC tarpaulin isn’t just a product. It’s a promise of protection, redefined.