Heavy-Duty Thickened PVC Tarpaulin – Waterproof, Tear-Resistant & UV-Protected Wholesale Canvas

When storms roll in without warning, what stands between your valuable equipment, inventory, or harvest and nature’s fury? Imagine a sudden downpour flooding a construction site, hail shredding through fragile covers on orchards, or relentless sun bleaching standard tarps until they crack and fail. These aren’t hypotheticals—they’re daily risks faced by industries from logistics to agriculture. The truth is, most conventional cover materials simply can’t withstand real-world demands. They leak, tear, fade, and degrade—often within months. But what if there was a tarp that didn’t just survive the elements, but thrived under them?

Three Layers of Defense: Engineering Strength Beyond Expectation

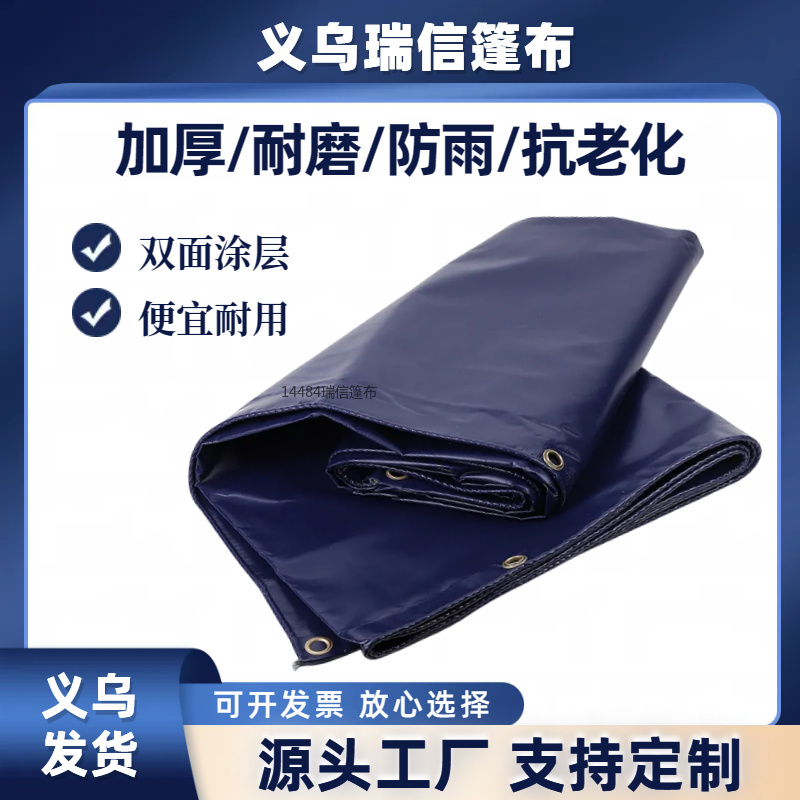

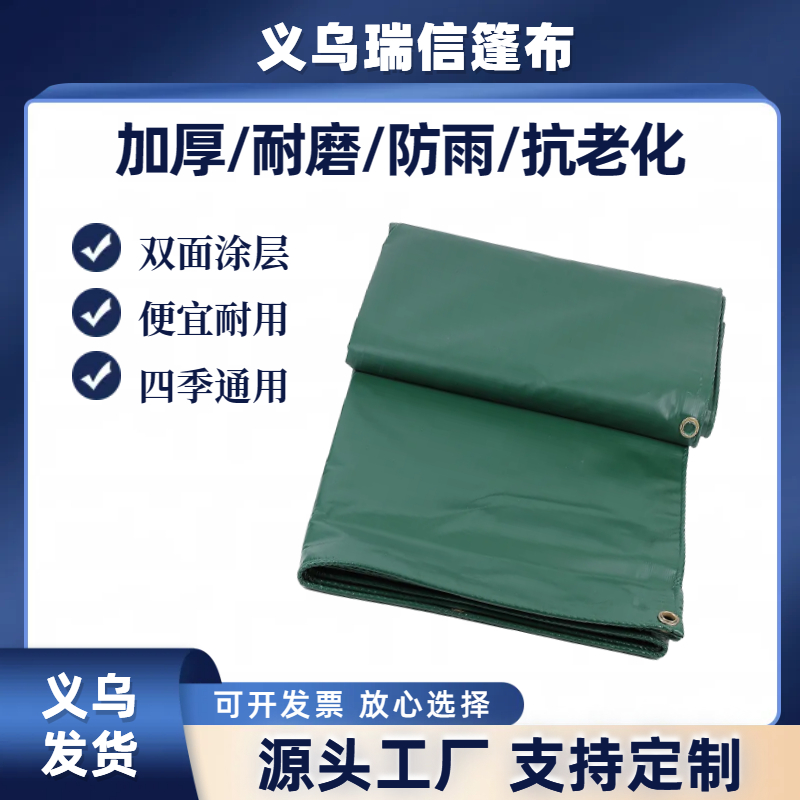

Our heavy-duty thickened PVC tarpaulin isn't built—it's engineered. At its core lies a revolutionary three-in-one protective system designed to outperform traditional canvas and thin plastic sheets. The foundation is a high-tensile, tightly woven base fabric that resists stretching and distortion under load. This isn’t just wrapped in PVC—it’s fully encapsulated with a dual-sided thick coating that forms a molecular barrier against water intrusion. Rain doesn’t bead up—it repels completely, leaving no chance for seepage even during prolonged exposure.

But strength isn’t only about thickness. The real innovation lies in how these layers work together. When stress hits one point, the dense mesh distributes force across the surface, preventing localized tears from spreading. Meanwhile, UV inhibitors aren’t merely added as afterthoughts—they're integrated into the polymer matrix itself, creating a material that resists photodegradation at the chemical level. This means the tarp won’t just look newer longer—it will perform like new, year after year.

Battle-Tested in Extremes: Real-World Performance Data

Laboratory tests are useful, but true reliability comes from field validation. In northern freight yards, our tarpaulins have endured temperatures below -20°C without becoming brittle or cracking during handling. Even after months of snow and ice accumulation, removal left no residue or structural compromise—flexibility remained intact.

In contrast, southern orchards subjected tarps to six consecutive months of direct tropical sunlight. Independent testing showed less than 8% reduction in tensile strength—far exceeding industry averages. On industrial docks, repeated forklift traffic across edges and surfaces caused abrasion marks but never compromised the integrity of the coating. These aren’t isolated cases; they represent consistent outcomes across diverse climates and operational stresses.

More Than a Cover: Unlocking Unexpected Applications

While originally designed for cargo and construction, users have discovered creative applications that highlight its adaptability. Farmers now use it as quick-deploy greenhouse roofing, leveraging its heat insulation and light diffusion properties. Livestock transporters install it as moisture-blocking curtains between compartments, improving hygiene and comfort.

Vendors at outdoor markets rely on it for instant stall setups—wind-resistant, quick to anchor, and printable for branding. Emergency responders have adopted it as rapid-shelter roofing and ground-laying barriers in disaster zones, where speed and reliability save lives. Whether protecting electronics at a festival or serving as a durable backdrop for events, this tarp transitions seamlessly across sectors.

The Devil Is in the Details: Where Most Tarps Fail, Ours Prevails

A tarp is only as strong as its weakest seam. That’s why we replace stitched hems with high-temperature thermal bonding—a process that fuses the edge shut without puncturing the material. Unlike thread-based seams that rot or snap, these sealed borders resist unraveling even under constant strain.

Corners feature strategically placed reinforced metal eyelets, positioned based on stress distribution modeling to prevent tearing when tied down. And the surface isn’t smooth—it has a subtle micro-texture that reduces water pooling while increasing resistance to scratches and scuffing. Every detail is engineered to extend service life, not just meet minimum standards.

Wholesale Efficiency: Smarter Protection at Scale

Buying in bulk isn’t just about cost savings—it’s about operational efficiency. With larger orders, the per-square-meter price drops significantly, especially when compared to frequently replacing inferior alternatives. We offer custom cutting services so you receive precisely sized tarps, eliminating onsite waste and reducing deployment time by up to 40%. For storage, our anti-stick treatment prevents layer adhesion during long-term stacking, preserving texture and function over time.

Built to Last: Five Years On, Still Going Strong

One mining fleet manager put it best: “We started with ten tarps to test. Now every truck in our fleet uses them.” After five years of daily use in dusty, abrasive conditions, early units still show minimal wear. Customers who initially purchased “just in case” now standardize across entire operations. Why? Because fewer replacements mean lower labor costs, reduced downtime, and less environmental waste. This isn’t just a product—it’s a long-term investment in resilience.

When the weather turns harsh and stakes run high, don’t settle for temporary fixes. Choose a tarp that works as hard as you do—engineered for endurance, proven in practice, and ready for whatever comes next.